INSITU MACHINING

Trusted Partners

Reliable Solutions

COLD CUTTING & BEVELLING

Clear Water Services Sdn Bhd’s cold cutting and beveling services. Low Clearance Split Frames (known as orbital cutter) are ideal for pipe maintenance and construction work in nuclear and fossil power plants, pipelines, oil platforms, petrochemical plants and refineries, as well as shipbuilding, pharmaceutical, food, beverage and other high purity piping applications.

Clamshell style machines the LCSF Low Clearance Split Frame is designed to “split” in half to fit over open-ended pipe. 13 standard-size machines are available to cut, bevel and counter bore pipe from 2-inch – 48-inch O.D. (DN50-1200) on all schedules and alloys.

Our LCSF split frame utilizes a cold cutting machining process, an operation that minimizes the risks associated with hot torch cutting and grinding, particularly important when hydrocarbons are present. In addition, torch cutting typically creates a heat affected zone (HAZ) and into duces airborne contaminants into the environment, unacceptable in many worksites and a potential health hazard.

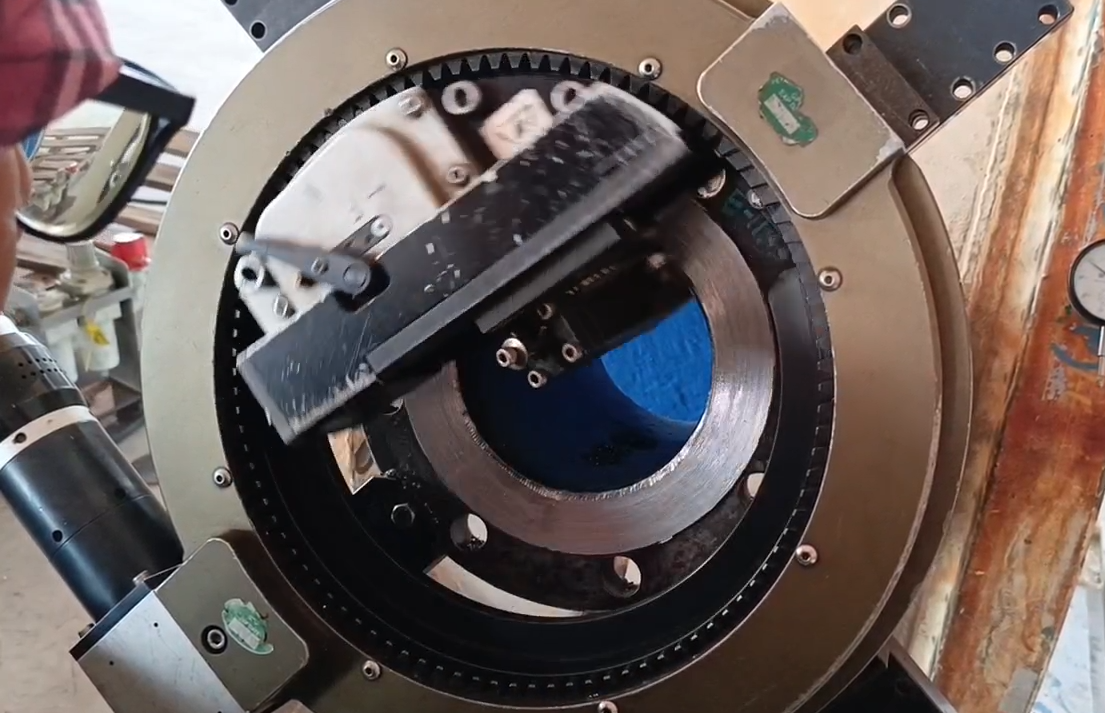

FLANGE FACING

Flange facing Machine is a compact, lightweight great for onsite machining. Externally and internally mounted which means that its easily mounted. Operates in any position. Flange Facing driven by pneumatic

Cut’s “O” ring grooves, vertical grooves, “V” grooves, raised face seat and flat face seat. Achieves finishes from 1.6 μm Ra to 6.3 μm (63CLA to 250CLA) ‘Gramophone’ finish when turning.

COLD TAPPING

Involves using drilling machines or mechanical tapping devices that operate without needing to pressurize the pipeline. This method is suitable for situations where it’s possible to temporarily shut down the flow.

Today engine lathes and CNC lathes are the commonly used machines for single-point threading for offsite services. On CNC machines, the process is quick and easy (relative to manual control) due to the machine’s ability to constantly track the relationship of the tool position and spindle position.

RETHREADING

Threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. CWS’ offer offsite and onsite rethreading services for our clients.

A common method of threading is cutting with taps and dies. Unlike drill bits, hand taps do not automatically remove the chips they create. A hand tap cannot cut its threads in a single rotation because it creates long chips which quickly jam the tap (an effect known as “crowding”, possibly breaking it. Therefore, in manual thread cutting, normal wrench usage is to cut the threads 1/2 to 2/3 of a turn (180-to-240 degree rotation), then reverse the tap for about 1/6 of a turn (60 degrees) until the chips are broken by the back edges of the cutters.

MILLING

We provided mill surfaces services. There are several different types of milling, from single milling beds to milling machines that travel in the X and Y direction, called XY Mills. Milling heads can also be attached to some flange facing machines for circular milling.

Typically, milling is undertaken on surfaces that are out of flatness. Milling these surfaces brings them back to their design or specified flatness and finish for the application.

Interested in a potential collaboration?

Get in touch with us